Company News

Don’t Let It Go To Waste

Energy Efficiency at Ammonia Plants: Waste to Power

Ammonia (NH3) is a chemical compound widely used to produce fertilizers like Urea, Ammonium Nitrate, and Ammonium Sulphate to name a few. Ammonia manufacturing is a very energy intensive process. High electrical load to drive the system auxiliaries along with large quantities of thermal energy for steam reforming, is required in the production process. This makes ammonia plants a perfect candidate to focus on energy efficiency and utilize every potential source of energy available onsite. One of these potential sources can be the byproduct gases that are released during the production of ammonia.

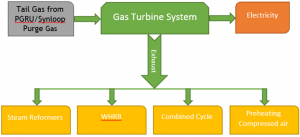

This article will discuss the utilization of byproduct gases like Tail Gas from PGRU (Purge Gas Recovery Unit) and Synloop Purge Gas in energy conversion equipment like gas turbines to generate power and heat simultaneously. OPRA gas turbines offers a perfect solution for utilizing these low calorific value and high hydrogen content byproduct gases that are difficult to use in conventional energy conversion equipment. Such gas turbine based cogeneration solution has the potential to save significant amount of expensive fuel, reducing the cost of operation and specific CO2 emissions per ton of ammonia produced.

INTRODUCTION

Ammonia (NH3) is the basic raw material used in downstream nitrogen fertilizer production. Among others, nitrogen based fertilizers constitute the major proportion in globally produced fertilizers. Ammonia production is the most energy-intensive process in nitrogen fertilizer production. This puts ammonia plants under scrutiny to reduce greenhouse gas emissions. Often ammonia producers are under pressure to reduce production costs in conjunction with higher production gains to be competitive in the market. All the above factors challenge the producers to constantly improve and advance their production processes.

A detailed analysis of the production process of ammonia holds the key to answer the challenges associated with an efficient design of process systems. Among other several areas of improvement, energy generation has the strong potential to keep the manufacturing costs at their minimum. Production of ammonia accounts for about 80-90% of the energy used in the manufacture of fertilizers (IEA, 2007). Energy in terms of electricity and heat, is an essential input for the ammonia industry, and ensuring its reliability and affordability is key for their sustained development. Development of new energy systems via implementation of advanced energy conversion equipment is essential to realize the above mentioned goals. Recent developments in the gas turbines industry to address the energy efficiency and flexibility to operate on unconventional fuels has created a new scope for ammonia industries.

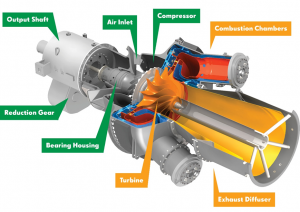

Gas turbines are a type of internal combustion engine. They primarily consist of a compressor, a turbine and a combustor. Gas turbines can be described by the Brayton cycle, in which air is compressed to a high pressure in the compressor section. Fuel is added to this compressed air in the combustor, providing a high temperature and high pressure gas. This hot gas is expanded through the turbine to produce mechanical power. Part of this mechanical power is consumed by the compressor. The remaining mechanical power can be converted into useful power such as thrust in aircraft, propulsion in marine turbines or electricity in power generation turbines. Gas turbines offer the most feasible cogeneration opportunities for users that have a minimum of 2:1 heat to power ratio. On account of advanced combustion technology of gas turbines they result in lower NOx and CO2 emissions, compared to direct combustion in burner or reciprocating engines.

Fig. 1: OP16 Gas Turbine System

INTEGRATION OF NEW GENERATION ENERGY SYSTEMS AT AMMONIA PLANTS

Ammonia is produced by reacting nitrogen and hydrogen together in right proportions. The following three types of processes can be used to manufacture ammonia:

- Steam reforming of natural gas

- Partial oxidation of heavy oil or waste oil

- Gasification of coal

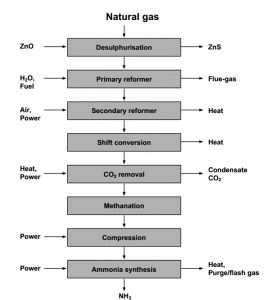

Steam reforming of natural gas is the most commonly used process in manufacturing of ammonia and 80% of the world ammonia production is based on this concept (IEA 2012). Figure-2 shows the typical manufacturing process of ammonia from steam reforming of natural gas.

Fig. 2: Block diagram of ammonia manufacturing process1

Ammonia production through steam reforming of natural gas is very energy demanding on account of heat inputs required at various stages during the process. It can be said that the heat to power ratio at ammonia plants is typically higher than 3:1. Implying there is a good match for gas turbine based cogeneration at these factories.

Natural gas is the main raw material for ammonia production with approximately 80% of world ammonia capacity being produced from natural gas (IEA 2012). High prices of natural gas in certain geographies and regulations to reduce greenhouse gases puts manufactures under stress to produce ammonia at competitive prices. In this regard it is important to reduce the reliance on natural gas or other fossil fuels for energy generation at ammonia plants. However, the energy generation is typically done through use of conventional energy conversion equipment like auxiliary boilers, gas turbines, steam turbines or engines operating on natural gas or other fossil fuels.

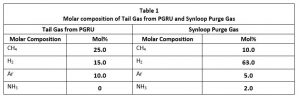

Alternate fuel sources within the ammonia plant to generate energy has the potential to control the cost of energy production. This can be done by using new generation gas turbines that can run on unconventional fuels like “Tail Gas from PGRU” or “Synloop Purge Gas”. To understand the behavior of Tail Gas we need to understand the ammonia synthesis process. Ammonia synthesis is operated in loop mode, since the conversion per pass is only 20-30%. The synthesis gas contains small quantities of methane and argon (inerts), which build up in the loop. In order to achieve an optimum conversion it is necessary to purge a certain quantity of gas from the synthesis loop to reduce the concentration of these inerts. This purged gas from synthesis loop, also called as Synloop Purge Gas, contains high amount of hydrogen, which can be recovered by installing a Purge Gas Recovery Unit (PGRU) (Nand and Goswami, 2009). The Tail Gas is derived as a byproduct gas from the PGRU after hydrogen recovery from Synloop Purge Gas. The Tail Gas from PGRU and Synloop Purge Gas typical molar composition is shown in Table 1. The Tail Gas from PGRU and Synloop Purge Gas has low and fluctuating calorific value making them difficult to be used in conventional gas turbines. On account of high hydrogen content of these gases they can result in knocking in conventional reciprocating engines.

To tackle different variety of fuels OPRA has developed specific combustors for its OP16 series of gas turbines. The OP16 gas turbine is specified with different combustor options i.e. 3A, 3B or 3C depending on fuel and emissions requirements. The OP16-3A and 3B gas turbines are designed for high calorific value fuels such as natural gas, diesel, well-head gas, LPG along with low emissions requirement. The third variation of the OP16 series of gas turbines, the OP16-3C, is capable to burn low calorific gaseous and liquid fuels like “Tail Gas from PGRU and Synloop Purge Gas”. The OP16-3C is a new generation gas turbine allowing industrial users to burn a variety of low calorific value fuels in it to generate reliable and continuous energy. Industries like ammonia manufacturers can make use of these gas turbines to generate energy from free fuel sources. This results in reduction of CO2 emissions from the plant along with sustainable generation of energy.

In order to make the most efficient use of the gas turbines it is wise to operate them in cogeneration mode. The objective of a gas turbine based cogeneration scheme is to produce electricity and to use the high grade thermal energy (hot gases at 580°C) from exhaust of the gas turbine for one of the following purposes:

- Steam Reformer: Reformers are typically operated at temperatures between 500-800°C, depending on the reforming stage. A gas turbine with high exhaust temperature matches this demand. In addition, gas turbine exhaust contains around 14% O2, which enables post-combustion to increase the temperature of hot air temperature entering the reformer, without adding fresh air. At present the heat for the primary reforming process is supplied by burning natural gas or other gaseous fuel, in the burners of a radiant box containing the tubes1. Thus the use of natural gas can be replaced by freely available hot gases from gas turbines.

- Waste Heat Recovery Boiler (WHRB): Using the hot gases from the gas turbine’s exhaust in a WHRB to generate steam for the process use in ammonia manufacturing or to drive a steam turbine. Again the exhaust can be post-combusted to match steam demand of the plant without adding fresh air in the boiler, resulting in higher efficiency of steam generation.

- Combined Cycle: The exhaust of the OP16 gas turbine can be used in the existing boiler to produce steam and thereby electricity in a combined cycle mode.

- Preheat the compressed air: In the secondary reformer internal combustion of a part of the feed gas with the process air is done to increase the conversion rate of ammonia. This process air also provides the nitrogen for the final synthesis1. The process air is compressed to the reforming pressure and heated further in the primary reformer to around 600°C1. This process air can be preheated with the gas turbine’s hot exhaust gases thus reducing feed gas consumption.

Fig. 3: Gas Turbine schematic for ammonia plant

All the above uses of the gas turbine’s exhaust results in higher combined efficiency of the system based on a free fuel i.e. Tail Gas from PGRU or Synloop Purge Gas. Such a solution reduces the CO2 and NOx emissions that are otherwise created from direct combustion of these fuels in a reformer or auxiliary boilers to generate heat.

In order to check compatibility of gas turbine, as a starting point, process flow and thermal requirements (pressure, temperature and steam flow rate) have to be analyzed. It may be necessary to add post-burners to match steam parameters required by the process. Depending on whether the turbine is desired to be operated in island mode or in grid-parallel mode, a few simple power connection modifications may also be necessary.

Most ammonia factories operate 24/7, making them ideal for gas turbine cogeneration plants. Gas turbines need minimal maintenance and down time. They are continuous machines that can operate for extended periods. The OP16 gas turbine, for instance, requires an inspection for every 8500 hours of operation. Equivalent to 354 days, this period can be scheduled to match the annual factory maintenance period. Apart from this OP16 gas turbine requires only one major overhaul for every 42,500 hours of operation. Implementation of gas turbine cogeneration at an existing ammonia factory is a common practice and it does not require significant modifications.

FEASIBILITY STUDY

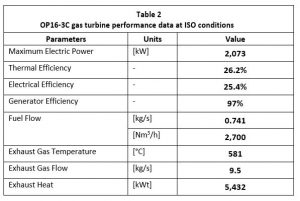

The technical and economic feasibility of gas turbines used for power and heat generation in ammonia factories, is a key tool to understand the actual implementation of such a solution. Table 2 shows the performance characteristics of OP16-3C gas turbine running on Tail Gas from PGRU at ISO conditions.

As it can be seen from Table 2, one OP16-3C gas turbine is capable of producing 2MW of electricity by using Tail Gas from PGRU as fuel. The resultant heat coming out from the gas turbine can be used for various purposes as mentioned in Section 2. This simultaneous production of heat and power using the OP16-3C gas turbine results in a best in class combined efficiency of approximately 85%.

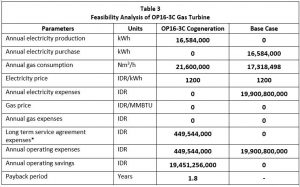

Table 3 compares the gas turbine based cogeneration to a base case where the gases like Tail Gas from PGRU are used in a furnace to produce only steam. It is quite evident that new generation gas turbines are capable of utilizing byproduct gases from ammonia factories with increased efficiency. By making use of such a technology the ammonia plants can ascertain high operational savings in terms of electricity and heat production. The feasibility is based on Indonesian currency IDR (Indonesian Rupiah).

The above feasibility analysis takes into account the following investments costs:

- OP16-3C gas turbine genset

- Waste Heat Recovery Steam Boiler

- Compressor for Tail Gas pressurization

- EPC costs for installation

- Maintenance costs for gas turbine

The OP16 is designed for minimal maintenance requirements with long service intervals. The above LTSA agreement expenses is for basic level which includes following services:

- Contract duration: 5 years

- 24/7 hotline

- Remote monitoring

- Annual Inspections

- Labour

- Spare parts

CONCLUSIONS

This paper presents the potential for new energy generation approach in ammonia production plants. It becomes quite evident from the study that new generation gas turbines that are capable on operating on off spec fuels like Tail Gas from PGRU and Synloop Purge Gas holds the potential to reduce emissions and lower the production costs at ammonia plants. The feasibility study presents a useful insight into the techno-commercial viability of this technology at ammonia plants. Operation of gas turbines such as the OP16-3C result in efficient generation of valuable electricity and heat from free fuel source with a quick payback period. As a result of the feasibility analysis, it is seen that OP16-3C gas turbine genset in cogeneration mode will produce annual operational savings of around IDR (Indonesian Rupiah) 19,451,256,000 in Indonesian market. These savings in turn will payback for the complete investment done for OP16-3C gas turbine installation within 1.8 years of operation. The application of such technology is also viable in various geographies around the world in ammonia plants, given the fact that energy is being generated from free fuel sources.

OPRA turbines offers new generation OP16 gas turbines to burn industrial waste gases and generate energy for the process use. This combined with minimal maintenance requirements becomes a value to the continuous operating factories like ammonia plants.

AUTHOR: Anshuman Pandey, Segment Sales Manager at OPRA Turbines

REFERENCES

- Best Available Techniques for Pollution Prevention and Control in the European Fertilizer Industry, 2000.